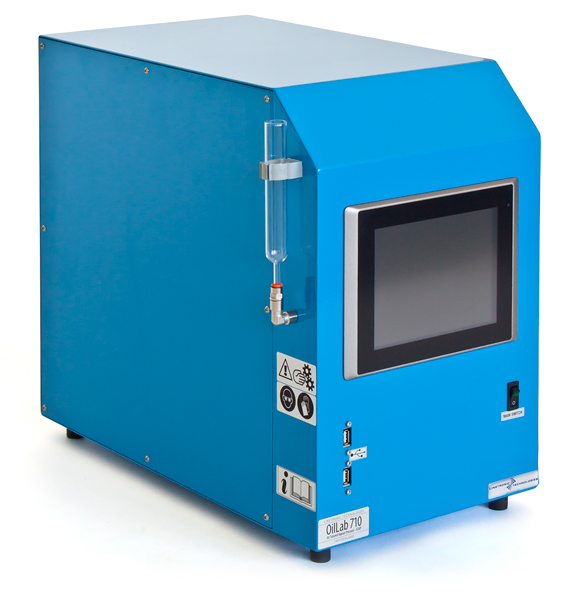

OilLab 710 Air Satured Vapour Pressure

Standards

ASTM D519, 1IP 394

CE marked

Subject: Gasoline

Automatic analyser for determination of Air Satured Vapour Pressure - DVPE

Principle of detection

A chamber of 15 ml is maintained at 0.1 kPa and 37.8°C. A quantity of 3 ml of sample, with a temperature of 0 °C, after the air saturation procedure, is automatically injected by means of a pneumatic injector inside the cell of 15 ml. Due to the temperature a certain volume of sample changes from the liquid phase to the gas phase. This mutation modifies the absolute pressure inside the chamber. When the stabilisation of the pressure is reached, the volume of the absolute pressure obtained will be considered as the total vapour pressure.

Main Features

Automatic system for sample conditioning in order to maintain the product at 0 °C

Automatic system for air saturation

Sample injection system

Integrated sample cell, maintained at a temperature of 37.8 °C

High quality pressure sensor

Pressure range: 0 … 2000 mBar / 0…177kPa

Resolution: 0.01 kPa

Max applicable pressure: 5 Bar

Precision: <2 mBar / 0.2 kPa

Vacuum pump efficiency 0.01 kPa

Touch Screen Panel PC:

TFT/LCD 8”

Resolution 1024 × 768, 16.2 M colours

2 USB ports for connection to external printer / PC

Cord cable with Shuko plug

User manual

Software Features

User friendly interface

All analytical parameters recorded

Customizable analysis parameters and methods

Customizable results report

Printable graphs and results

Self-identification of the typology of the analysers connected

The software includes:

Analysis Menu

Standard method as per ASTM / IP / ISO / EN / DIN… norms of reference

Unknow sample

Audible alarm and displayed messages at the end of the analysis and in case of errors and/or malfunctions

Diagnostic Menu

Direct access to all analog, digital, inputs and outputs

Selectable value displaying: °C / Volt

Calibration Menu

Automatic calibration of each temperature probe

Last calibration date referred to each single probe displayed and relative data printable

Display of calibration diagram

Insertion of offset values

Standard and advanced calibration modes

Data Utilities

Fields for introduction of operator and product name

Archive viewer for files recall

All analysis stored in Excel® compatible format

Storage capacity for more than 60’000 analysis

LIMS compatible

Electrical Supply

220V ± 15% / 50 to 60 Hz

115V ± 15% / 60 Hz

Ambient Temperature

Max 35 °C

H.R. 80%

Weight:

15 kg

Dimensions

width: 30 cm

depth: 52 cm

height: 45 cm

Spare Parts

LAB-700-018: PT100 cell

LAB-700-019: pressure sensor 0…177 kPa

LAB-700-210: PT100 conditioning

LAB-700-022: set of o-ring for conditioning

LAB-700-123: o-rings set for cell

LAB-700-202: solenoid valve

LAB-700-204: heater

LAB-700-210: Teflon syringe

LAB-700-255: vacuum pump

LAB-xxx/003-04: fuse 6.3 AT, box of 10 pcs.

LAB-xxx/007-04: fuse PCB 1.6 AT, box of 10 pcs.

Calibration Tools

OilLab 80: calibration decade box – PT100 simulator

OilLab 81: set of connectors and cables for cold range

Alternative Products

A sentence here about related products with image links below to products you want customer to consider.